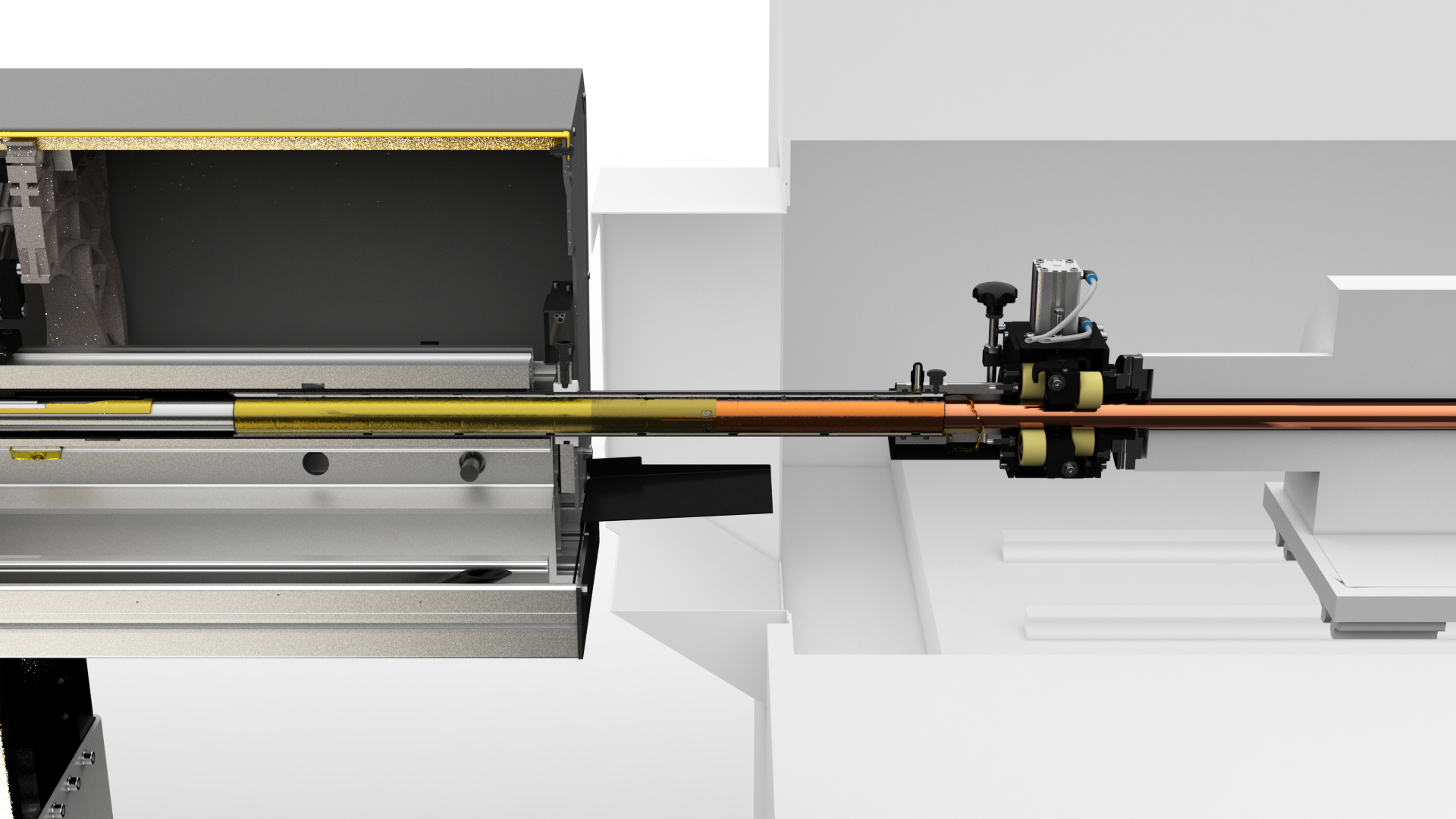

Area between bar feeders and machine tool

The RS technology was specially developed for machine tools in which a headstock moving in the Z-axis causes highly variable distances between the bar feeders and the machine tool. The guidance of the material bar between the loading magazine and the spindle has a decisive influence on the running smoothness and therefore also on the quality of the machining process. For this reason, large unguided areas, which change significantly over the course of the machining process, especially in the long turning process, should be avoided wherever possible.

Innovative solution from FMB

In bar feeders equipped with RS technology from FMB, the guide channel is connected directly to the spindle of the machine tool via a movable guide module. This means that the guide channel follows every movement of the headstock and there is never an unguided area. The transition between the bar feeders and the machine tool is optimally guided. The continuous oil-flooded structure ensures that the material bar is guided right up to the spindle. The steady rest is connected to the spindle of the machine tool and provides maximum support for guiding the material bar. In this way, the RS technology enables tarke performance in the turning process through maximum guide quality with minimal vibration and noise.