Products ▸ Handling systems ▸ unirobot

unirobot

System structure of unirobot

Electro-sensitive protective equipment

Free positioning of the robot without any enclosure or safety...

Electro-sensitive protective equipment

Free positioning of the robot without any enclosure or safety fence. Safeguarding of the robot work area using a floor scanner. Detection of unauthorized access via sensors, immediate stop of robotics if required.

Protective fencing system uniprotect

The entire danger zone of the handling system, including the...

Protective fencing system uniprotect

The entire danger zone of the handling system, including the buffer, is protected by the individual safety fence system

Compact handling system

Compact automation cell with integrated handling system including buffer. Optional...

Compact handling system

Compact automation cell with integrated handling system including buffer. Optional storage on rails, allowing lateral movement for free access to the working area of the machine tool.

Buffer systems from unirobot

Carousel

A carousel storage unit is integrated into the automation cell,...

Carousel

A carousel storage unit is integrated into the automation cell, which holds both unfinished and finished parts. Raw parts are loaded from the outside during operation. The carousel storage unit rotates in cycles and in this way transports the raw parts into the automation cell, where they are removed by the robot. The robot also places the finished parts on the carousel storage unit. The rotary movement transports the finished parts back out to the operator.

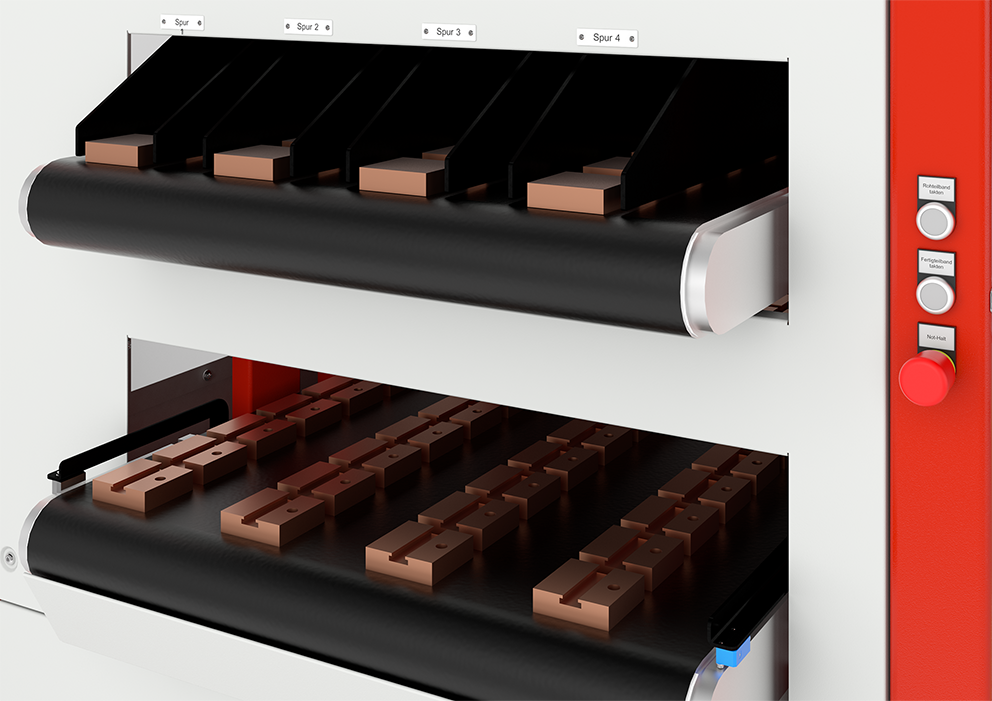

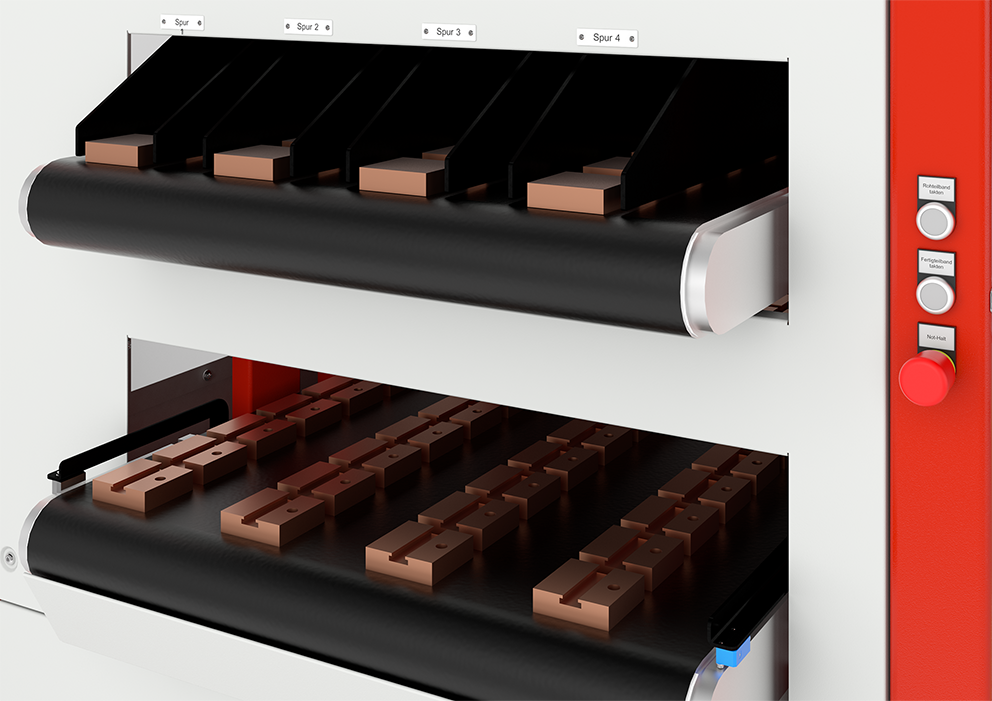

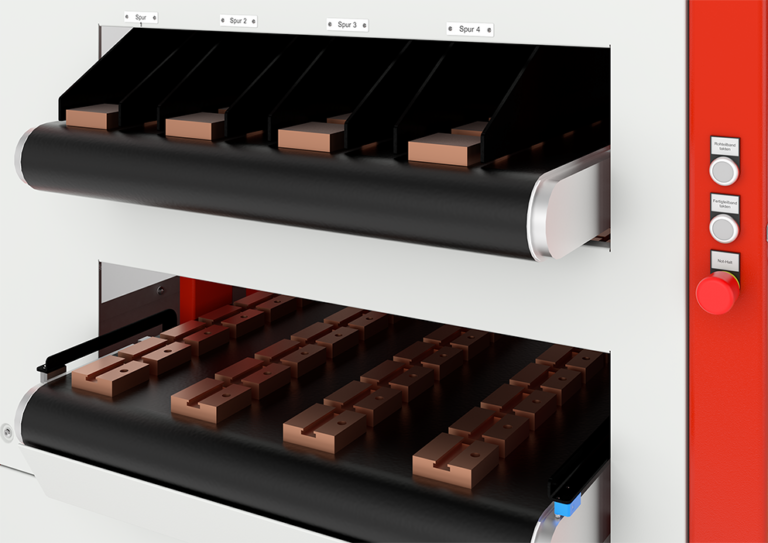

Conveyor belt

The automation cell is equipped with conveyor belts for feeding...

Conveyor belt

The automation cell is equipped with conveyor belts for feeding the raw parts and removing the finished parts. The operator places the raw parts on feed lanes and then automatically transports them to the automation cell. The robot removes the raw parts from one conveyor belt and places the finished parts on the other. As soon as the finished parts leave the automation cell, the operator can remove them.

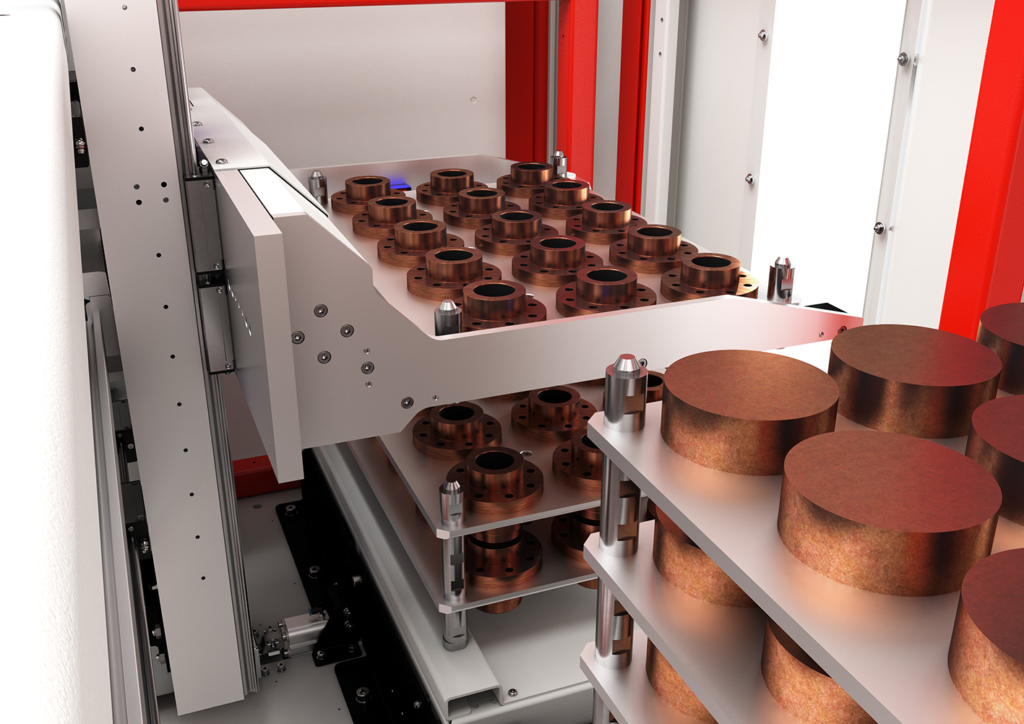

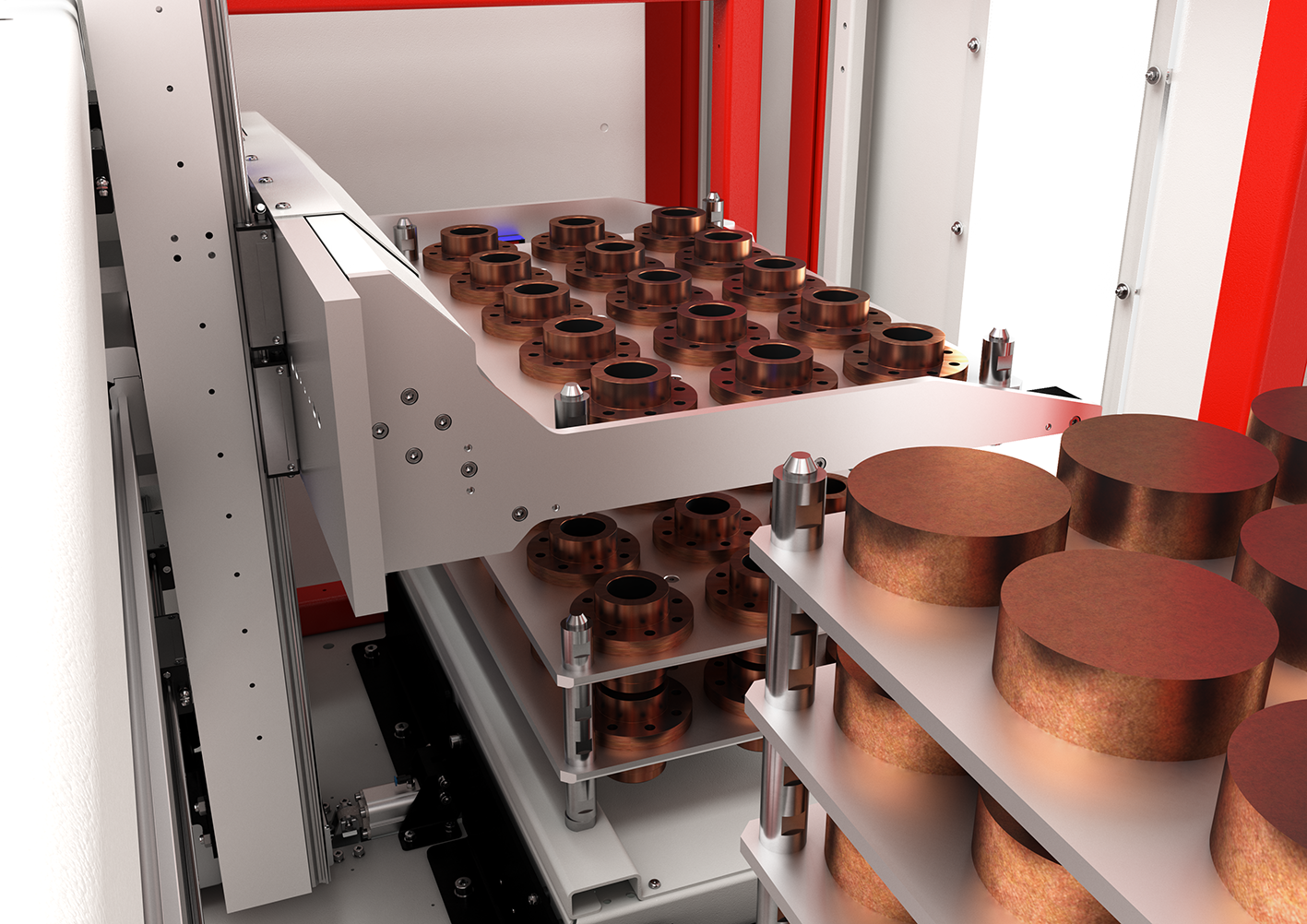

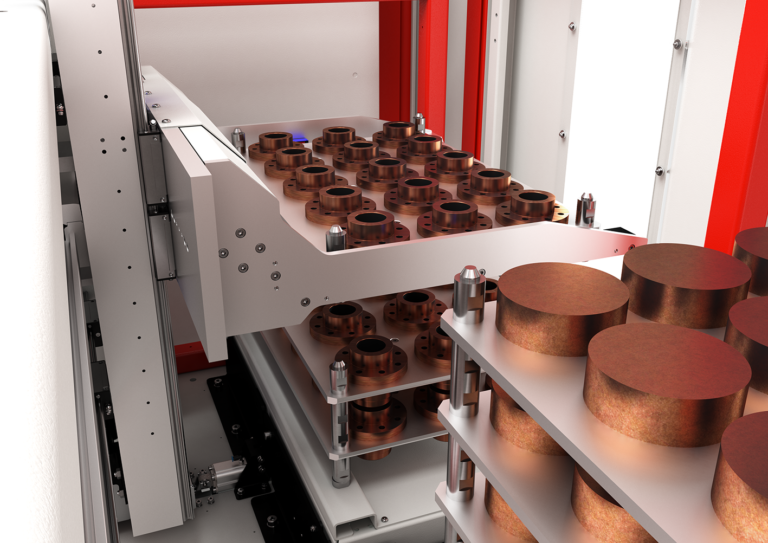

Pallet changer

A rack system, which can be loaded with workpiece carriers...

Pallet changer

A rack system, which can be loaded with workpiece carriers from the outside, buffers the raw parts. In the automation cell, a pallet changer lifts the workpiece carrier from the rack. The workpiece carrier is made available to the robot for removing the raw parts and loading them with finished parts. The workpiece carriers loaded with finished parts are transported by.

Trolley

The automation cell has one shaft each for the raw...

Trolley

The automation cell has one shaft each for the raw part trolley and the finished part trolley. First, the raw part trolley is pushed into the cell and is ready for removal by the robot. Another trolley is loaded with finished parts by the robot in the automation cell. When the maximum loading height is reached, this is replaced by an empty trolley. Workpiece-specific profiles ensure that the unfinished and finished parts can be stacked safely.

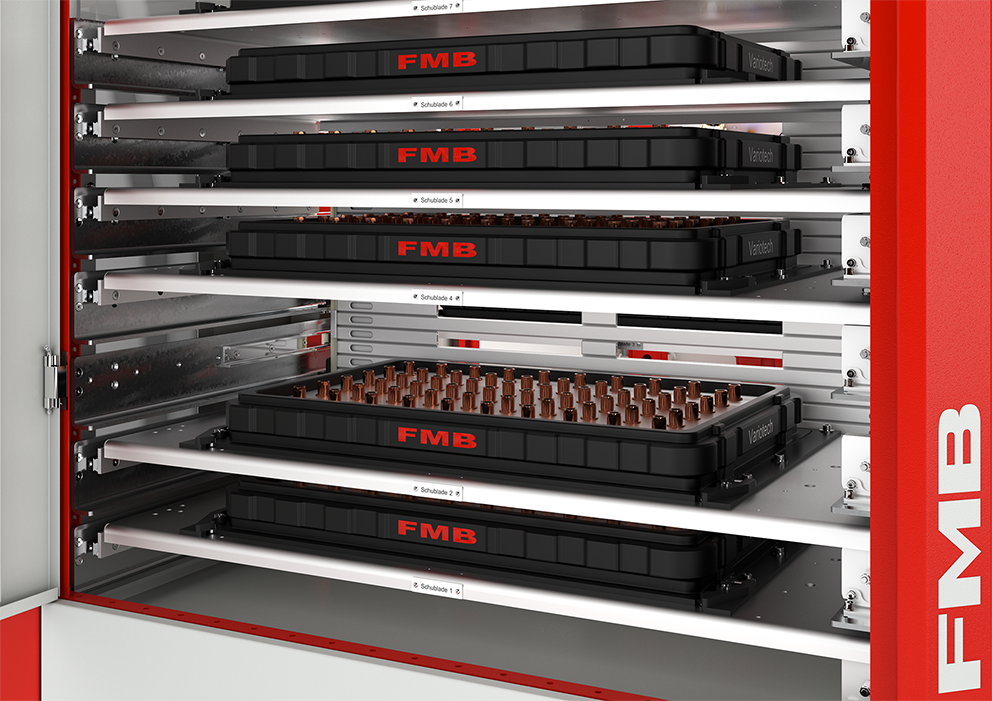

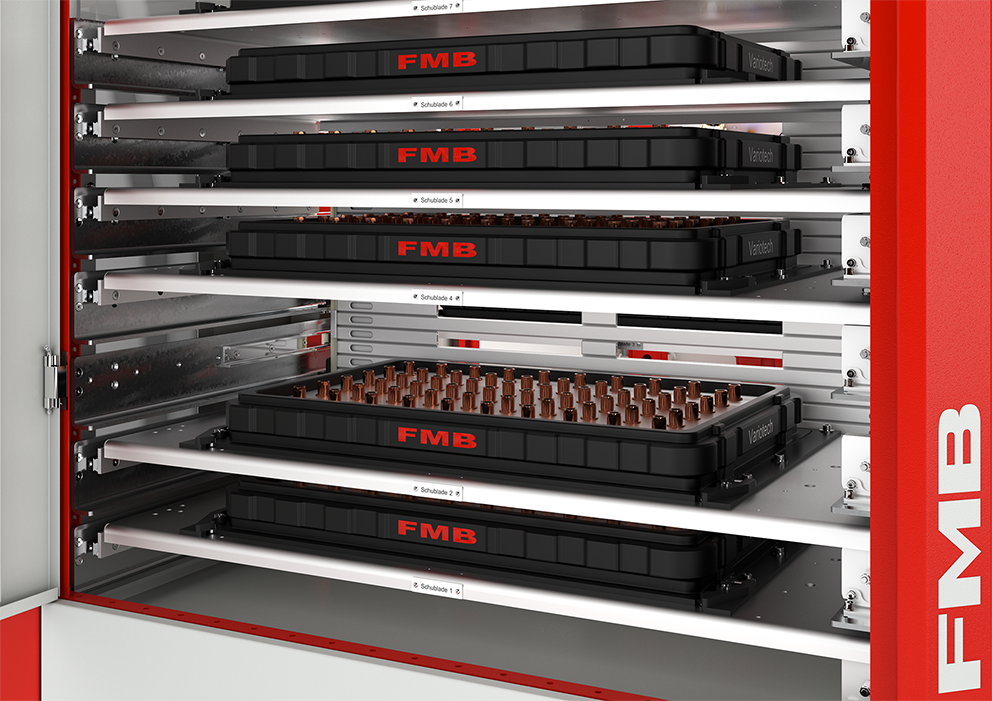

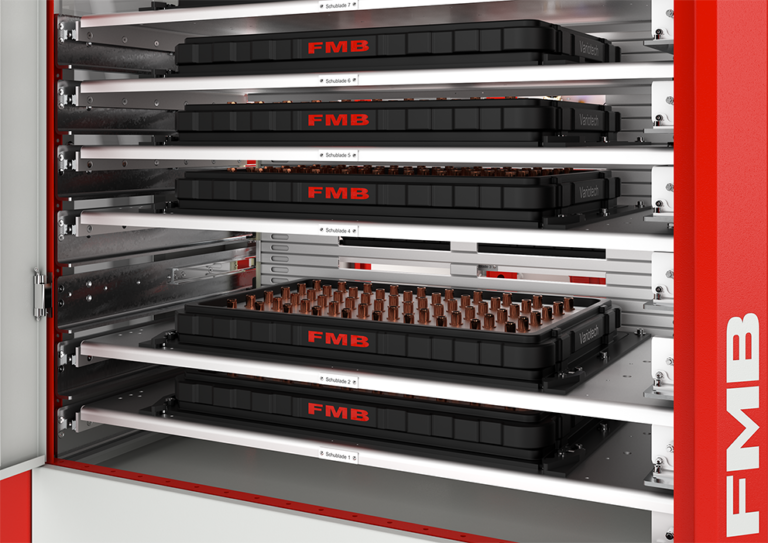

Drawer

The blanks are placed in workpiece carriers and fed to...

Drawer

The blanks are placed in workpiece carriers and fed to the handling system via drawers. The drawers are arranged one above the other and can be filled with blanks from the outside. One drawer at a time is pneumatically moved into the working position, which is then available to the robot. The workpiece carrier is returned to the outside via the drawer system and the finished parts can be removed.

Equipment from unirobot

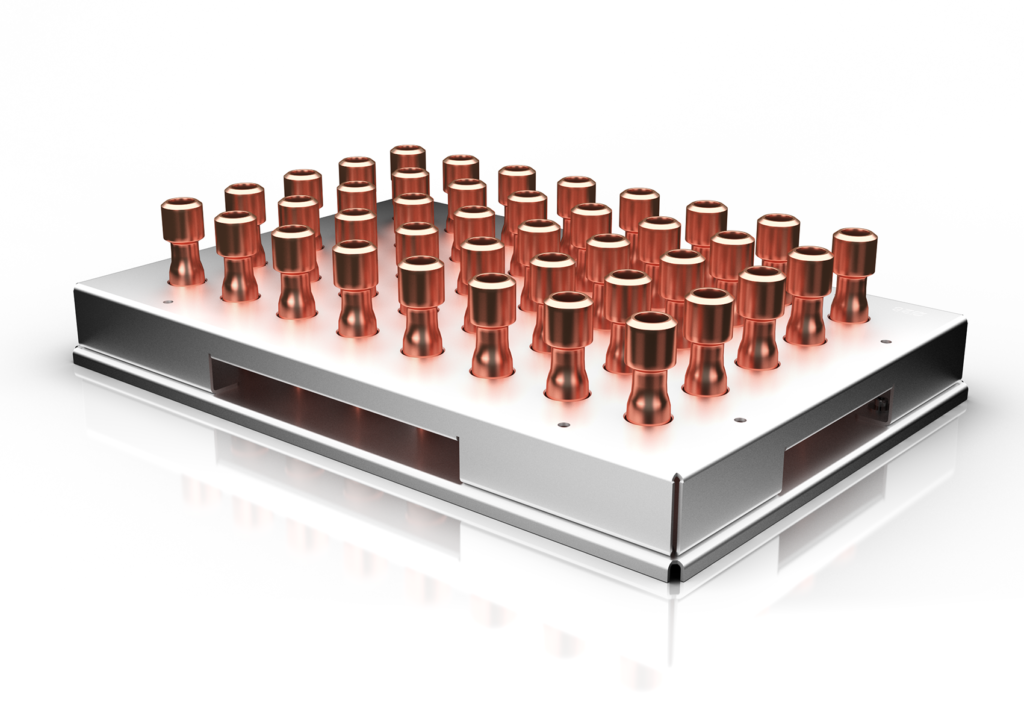

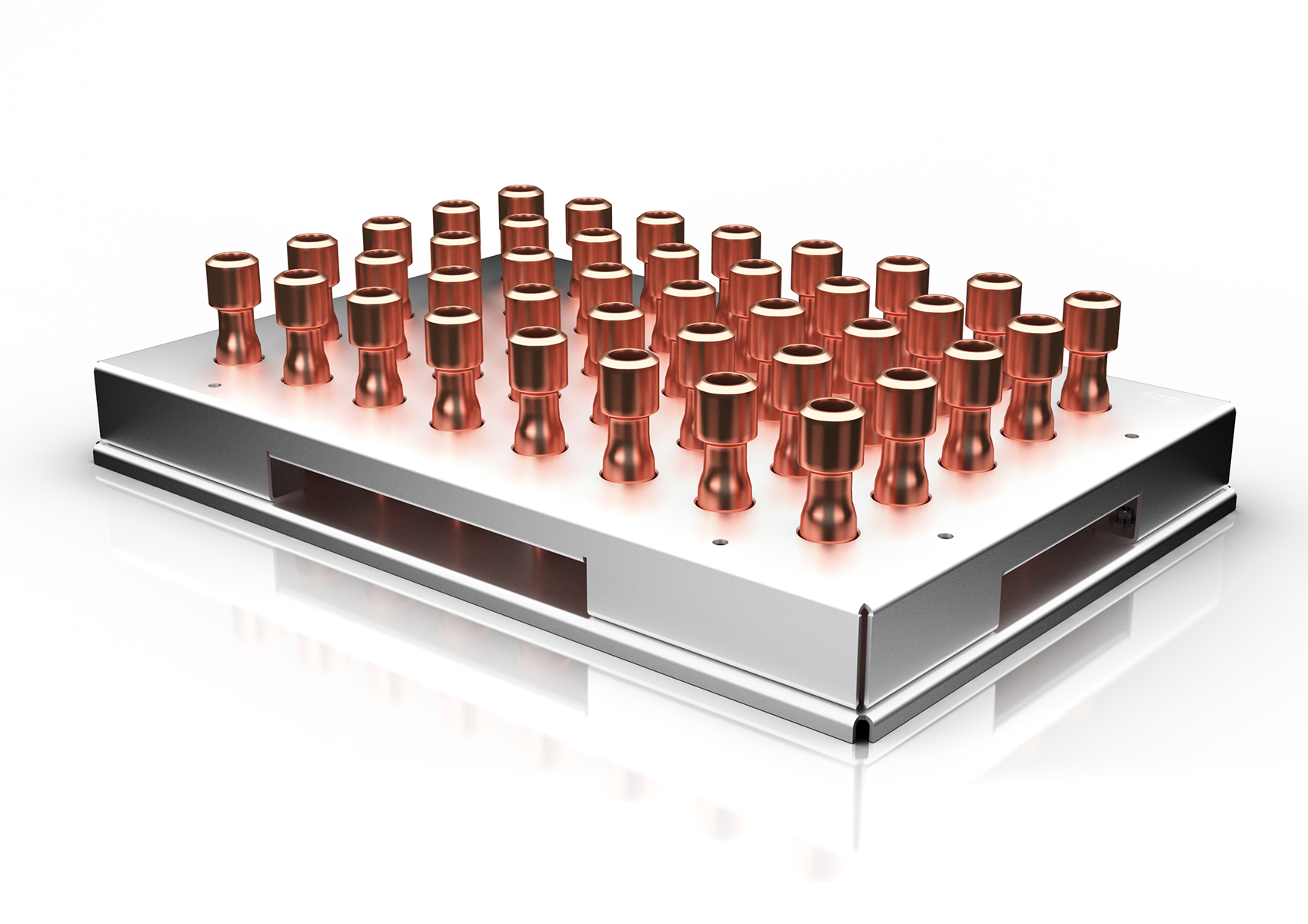

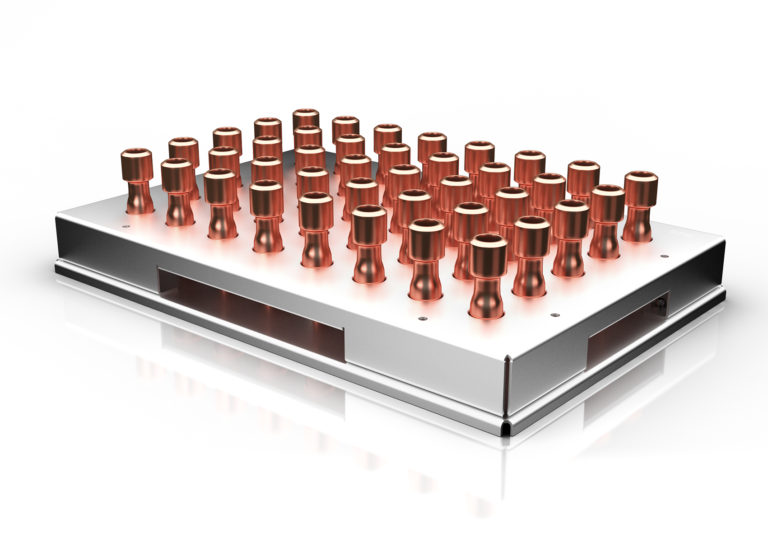

Workpiece carrier

FMB uses workpiece carriers in 600 x 400 mm format...

Workpiece carrier

FMB uses workpiece carriers in 600 x 400 mm format as standard. The range includes far more than the universally applicable ABS thermoforming trays with adjustable template. Whether milled workpiece carriers, made of sheet metal or wire baskets: the right solutions are available for every conceivable requirement.

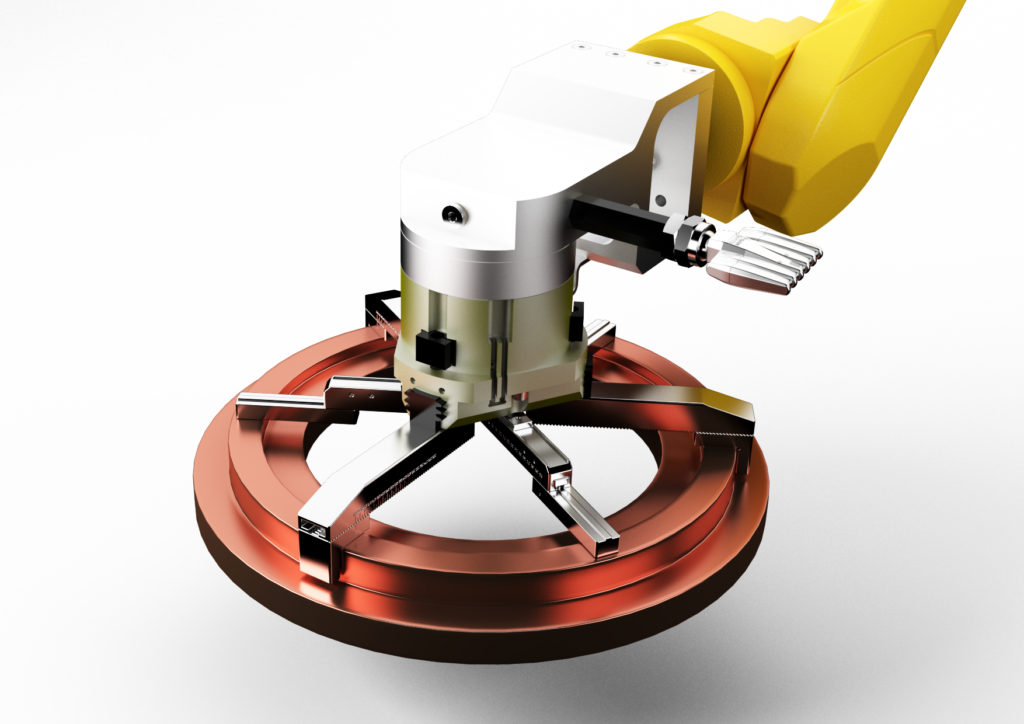

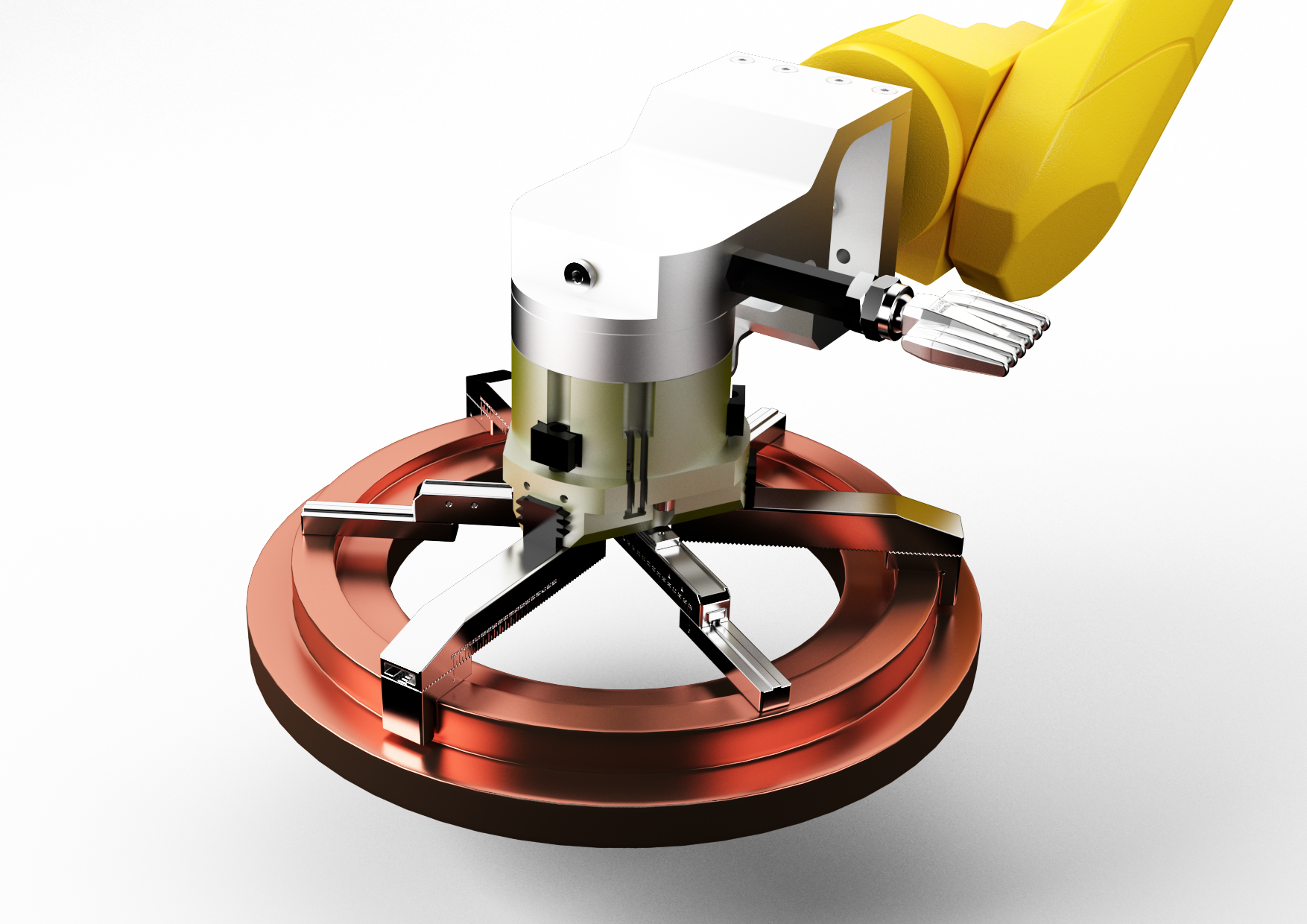

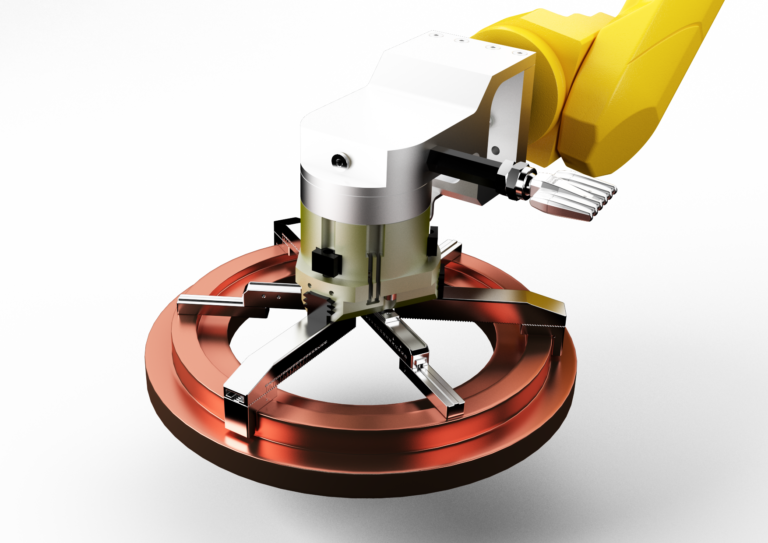

Gripper

The gripper plays a decisive role in the transfer of...

Gripper

The gripper plays a decisive role in the transfer of workpieces.

FMB offers the optimum gripper system for every requirement.

Depending on the workpiece, the type of gripper and the use of workpiece-specific gripper jaws are determined.

This allows workpieces of different materials, surfaces and geometries to be handled optimally.

All grippers can be configured in single or various multiple variants.

This means that the workpiece transfer is precisely tailored to the process.

The FMB quick-change system guarantees fast and tool-free changing of the various grippers.

Robots

A wide selection of industrial robots from leading manufacturers FANUC...

Robots

A wide selection of industrial robots from leading manufacturers FANUC and YASKAWA covers all the requirements of automated production. All models are characterized by simple operation with an equally clear and ergonomic HMI – and open up complete flexibility for production. Textual programming is carried out via teach-in or CAD-supported offline. High variability is ensured by up to six axes and free programming. FMB integrates robots with reaches of up to 4,000 mm and payloads of up to 1,000 kg, tailor-made for the respective handling system.

Functions of unirobot

Do you have questions about the product?

Contact our product experts now at

Speak directly to our sales department or use the contact form for your individual inquiry.