Products ▸ Handling systems ▸ base

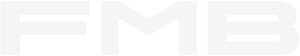

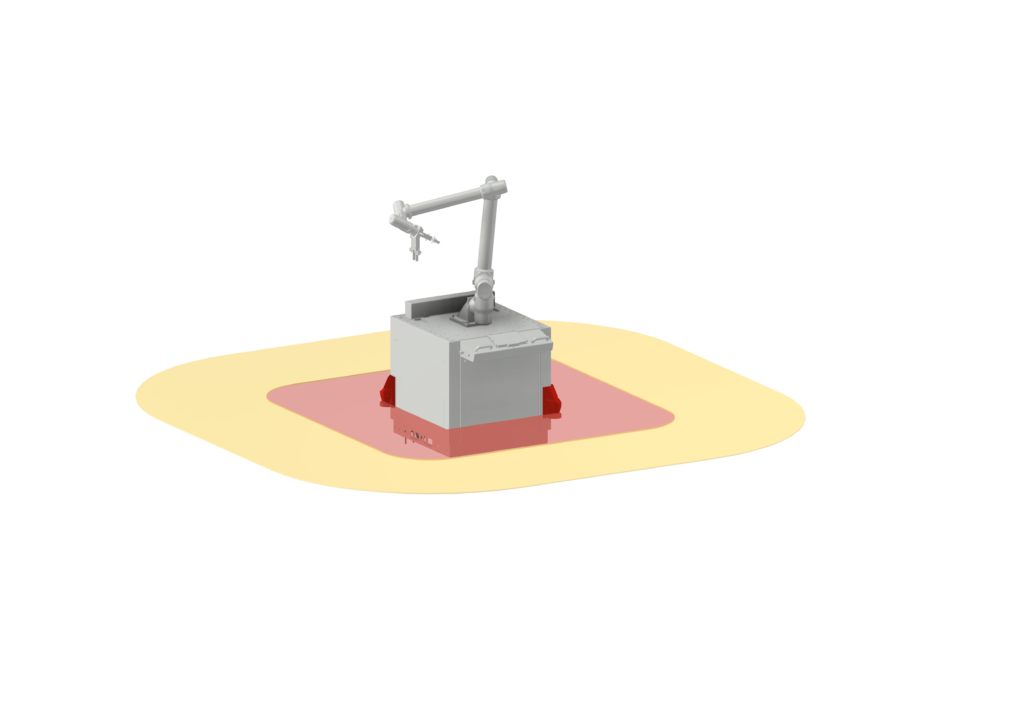

base

The modular automation system from FMB.

The various modules of the modular automation system can be combined plug & play to create a suitable complete system for your application.

We have the optimal economical automation solution

Thanks to its consistent modularity, the new FMB BASE enables efficient process automation in a wide range of applications. The product remains adaptable and can be expanded at a later date. In this way, we guarantee both functionality and sustainability.

Possible applications

- Machine loading

- Component processing

- Check

- Assembly and joining

- Packing

- Palletizing

- and much more.

Advantages at a glance

- Also for small and medium quantities

- Increasing productivity

- Flexible use

- Sustainably adaptable to new tasks

- Increasing quality

- Relieving staff

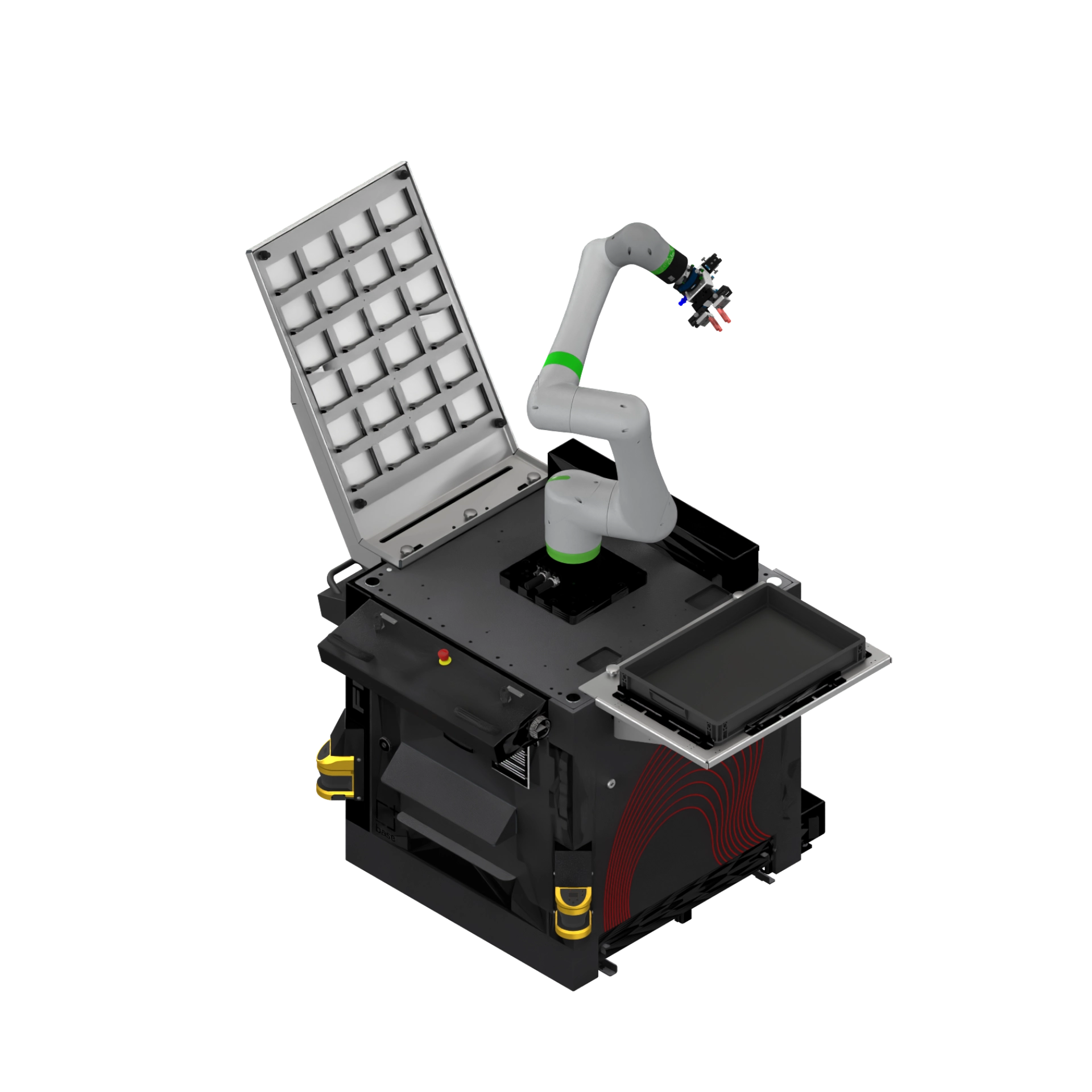

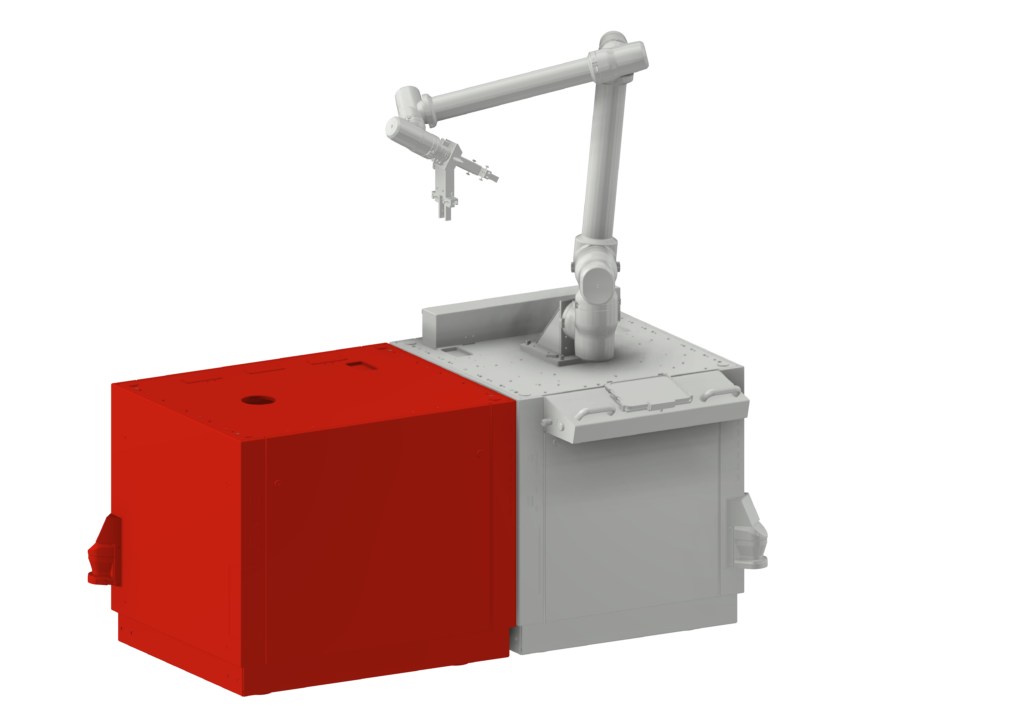

Base module:Base

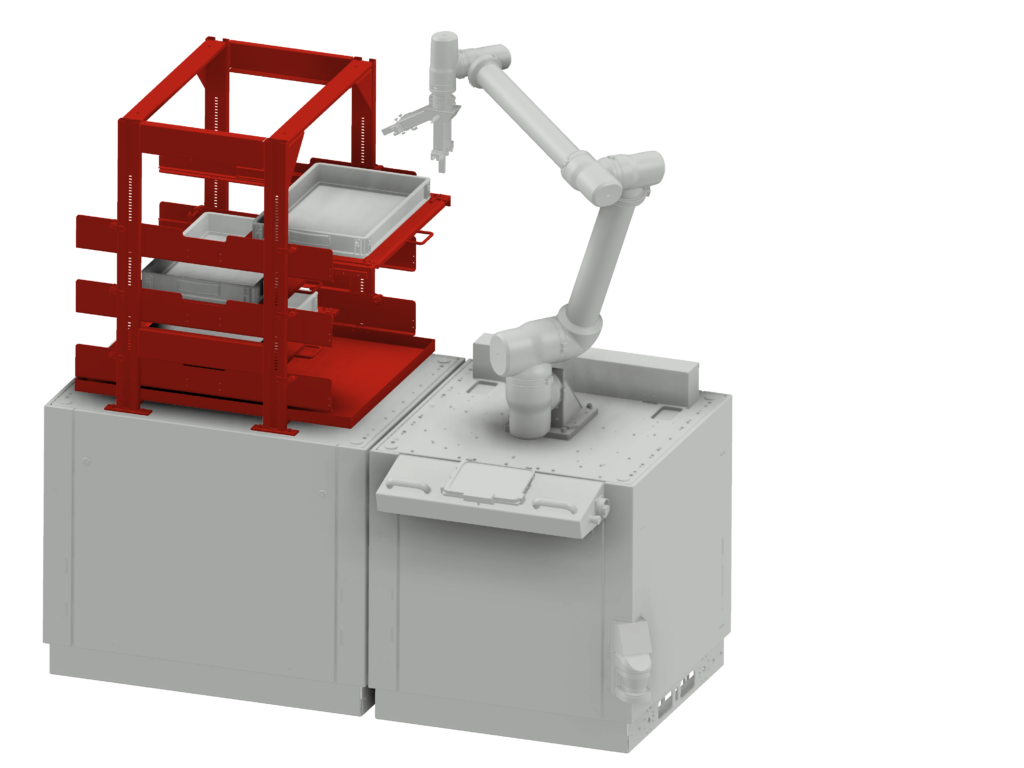

The basic module is the central component for all other modules. The torsion-resistant base body is the basis for all signals, commands and movements. All media are pluggable. Swivel castors enable flexible use. Alternatively, floor fixings allow the automation system to be used in a fixed location.

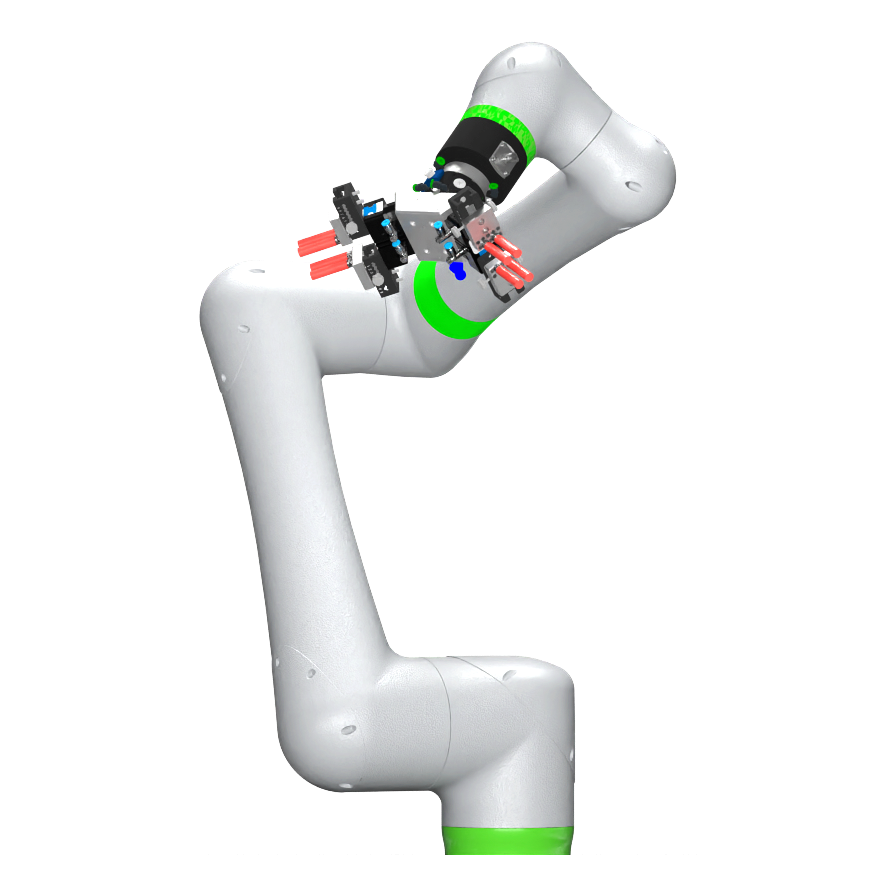

Robots

The industrial robot can be selected as flexibly as the modules of the modular automation system can be configured. Various robots from the manufacturers Fanuc and Yaskawa are available.

HMI operation

- Smart, web-based user interface

- No-code programming

- Operable with any web-enabled end device

- Freely configurable dashboards

- Open interfaces for loT communication and remote maintenance

Station

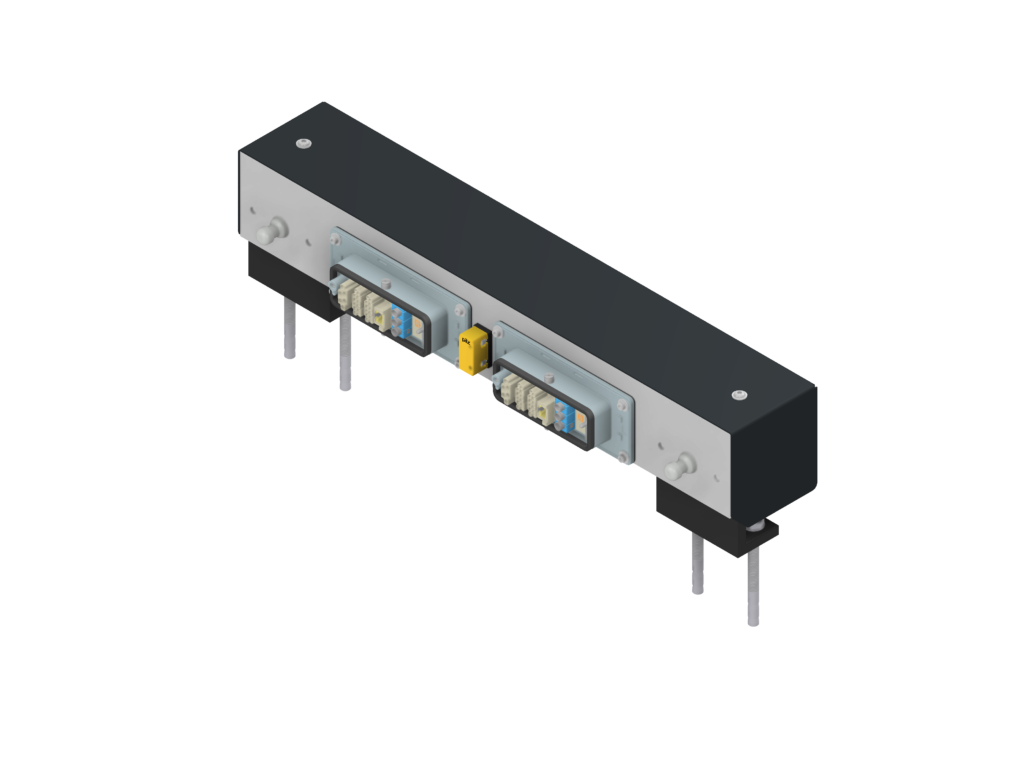

A station at each work location on the base supplies all the necessary signals.

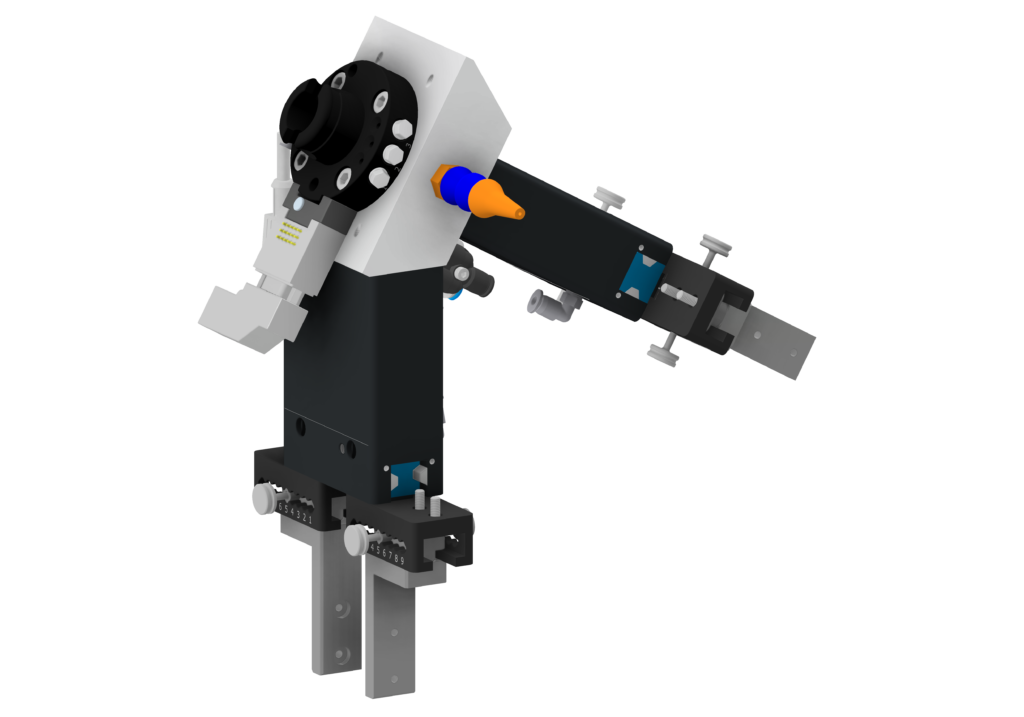

Tool-Tool

The application determines the tool – from component handling (gripping, suction, etc.) to machining (deburring, grinding, polishing, etc.) and joining (welding, gluing, etc.). A quick-change system means that tools can be changed in next to no time.

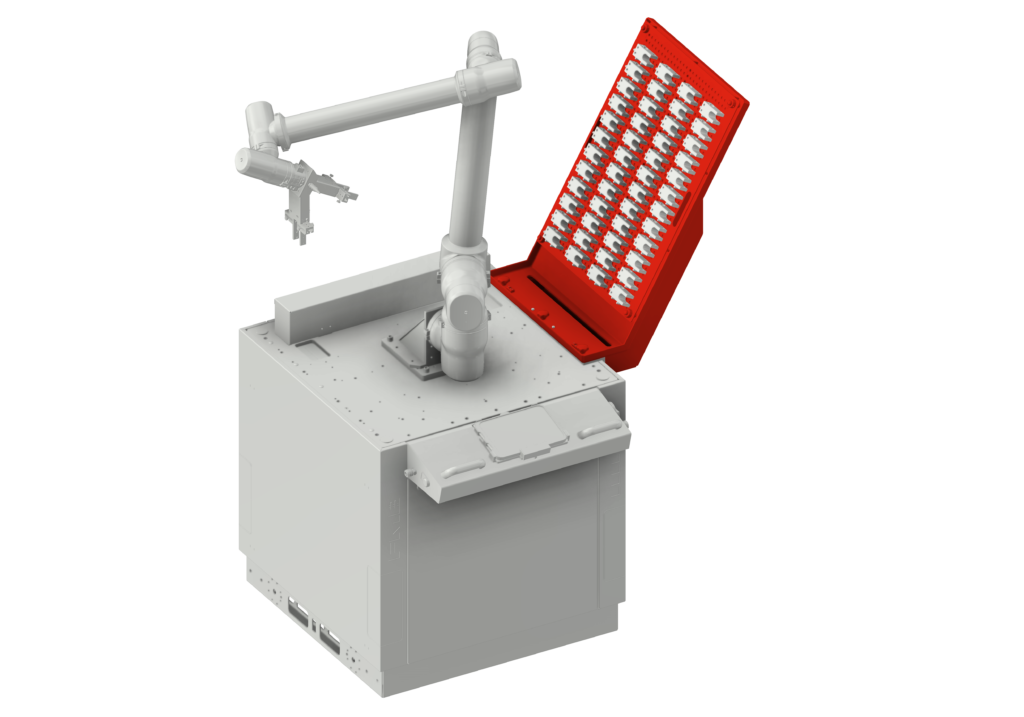

Function modules

for functional extensions such as machining, joining, cleaning, detecting, testing, measuring, but also cutting, holding, turning, turning, positioning and packaging for component feed / component removal as inclined plane, workpiece carrier, bulk material, bin picking, etc.

Direct modules

Direct modules extend the basic module. This makes it easy to increase the robot’s working area, feed and remove components and integrate additional functions.

Safety modules

The security of the overall system can be established in different ways.

Extension modules

Extension modules can be connected to the base module. This means that the robot’s working area can be significantly increased and additional modules for function and safety can be added quickly.

Support

We do not leave our customers to solve their automation tasks alone! A comprehensive range of support services from FMB guarantees reliable and efficient implementation

Do you have questions about the product?

Contact our product experts now at

Speak directly to our sales department or use the contact form for your individual inquiry.