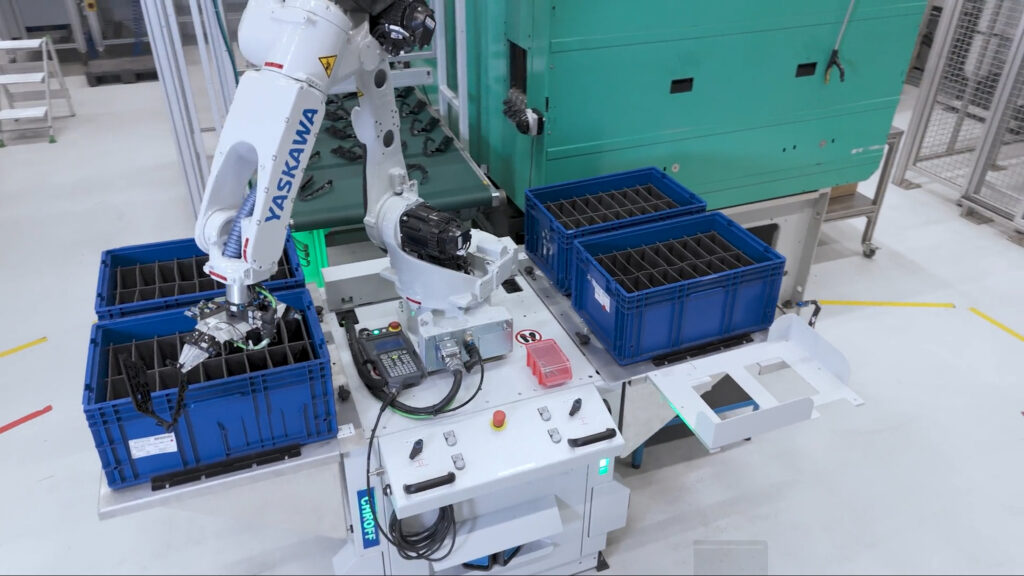

The company Chroff Kunststofftechnik GmbH from Bamberg specializes in the production of complex and high-quality plastic components for various industries. Injection-molded parts, which are produced in large quantities for a current order, have to be sorted after production and placed in KLT containers. Chroff has automated this process with a handling system from FMB Maschinenbau. The modular handling system base from FMB, which is equipped with the YASKAWA GP12 industrial robot, is ideal for this task and can make full use of its strengths.

Powerful camera system

The finished injection molded parts are discharged on a conveyor belt and transported to the KLT containers provided. The complex geometry of the parts and the non-oriented position on the conveyor belt previously made subsequent processes more difficult. In addition, left and right-hand components are produced by the injection molding machine and run off the conveyor belt together. These have to be sorted separately into the correct container. In the past, a specialist took over and placed the parts in the corresponding KLT containers. “The big challenge in automating the removal process was recognizing the workpieces on the conveyor belt,” explains Fabian Schäfer, electrical designer at FMB. Michael Vogel, Head of Technical Design at FMB, adds: “FMB has been working with optical systems for component recognition for a long time and has been able to build up a great deal of expertise in this area. FMB has implemented many projects in the area of chaotically stored components and bin picking in recent years. The company has worked extensively with various cameras and vision systems. The company relies on the all-in-one camera from Keyence with integrated AI to meet the requirements here. This provides the robot with all the necessary data for orienting the components so that it can grip the components individually in a suitable position. By supporting artificial intelligence, the camera is also able to carry out various checks. It could conceivably search for production errors or recognize texts, codes or colors. Here, the camera checks whether the component is on the right or left. The robot also receives this information. The components are thus placed in the KLT containers in a reliable and correctly sorted manner. A YASKAWA GP12 is used. With a payload of 12 kg and a reach of 1440 mm, the 6-axis industrial robot is perfect for handling parts and is an established component in FMB’s handling systems. FMB and YASKAWA have a long history together. FMB has been a system integrator for industrial robots from YASKAWA for 25 years. Over the years, the two companies have grown together. Initially, the focus was primarily on loading and unloading tasks for industrial production, but today the spectrum is much broader. Automation is in demand in all sectors. Joining and assembly, packaging, measuring, labeling or, as in this case, the removal and sorting of complex injection-molded parts.

Modular and flexible – FMB base

The base handling system from FMB used here is characterized by its consistent modularity. A standardized base module is equipped with an industrial robot suitable for the area of application. Various gripper and tool systems cover diverse areas of application and the base can also be adapted to specific processes with standardized extension and function modules. This allows the handling system to be quickly and economically designed to meet the respective requirements. It can also be easily adapted or extended to other processes for subsequent orders. A station system, which ensures the energy supply, makes the handling system, which is mounted on rollers, mobile. In this way, it can be docked to other stations and cover several processes at different locations and machines in the company with one handling system. The “container feeding” module used here offers pick-up areas for KLT containers directly on the handling system, into which the robot places the parts. The double gripper is precise and picks up two components at the same time. As Chroff also produces parts on the same injection molding machine that can only be handled with one suction cup, the double gripper can be easily changed using a quick-change system.

Automation and skilled workers hand in hand

The skilled workers at Chroff, who are no longer tied up sorting and removing parts, are now available for logistics and monitoring the entire process. The fact that the FMB base has a non-contact protective device is a great advantage here. This does not require any separating protective devices such as fences or enclosures. Direct access to the conveyor belt and the KLT containers is possible at all times. This does not interfere with the unloading process. Radar scanners on the handling system detect when people enter the danger zone. There are two zones. If the area marked in yellow is entered, the robot slows down its working speed but continues to work. The area marked in red delimits the direct danger zone. If this is entered, the robot stops immediately. If the marked areas are left again, the radar scanners also detect this and the handling system continues the unloading process independently. This makes it easy to check the fill level of the KLT containers or to replace them with empty ones if necessary without intervening in the process. Knowledge of how to operate the handling system is also not necessary. After a brief introduction, the Chroff employees and the FMB base work in parallel and hand in hand.